-

About

-

Products

- By Timber Product

- Cladding

- Decking

- Joinery

- Screening

- Panelling

- View all

- By Application

- Exterior Cladding / Siding

- Exterior Rain Screen

- Exterior Roofing

- Interior Walls & Ceilings

- Soffits

- Screening, Fins & Battens

- Windows, Doors & Joinery

- Posts & Beams

- Accessories + Samples

- Coatings

- Fixings

- Samples

-

Shop

- Samples

- Timber Samples

- Architectural Sample Box

- View all

- Accessories

- Coatings

- Fixings

- View all

-

Resources

- By Resource Type

- Technical Data Sheets

- Guides & Manuals

- Technical Articles

- Profile Drawings

- View all

- How To

- How To Specify

- How To Install

- How To Maintain

- Projects

- Contact

Grain Orientation and Timber Performance

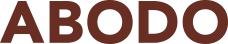

When wood, which has a high moisture content as it grows, is dried, different contractions occur depending on the orientation of the cut made and the resulting arrangement of the growth rings.

Although this varies through different species, the deformation is always greater in the direction tangential to the rings than in the radial direction.

Grain orientation has a massive impact of the stability and performance of wood in exterior applications.

Heartwood performs differently during the drying process, and also has an impact of performance of exterior timber.

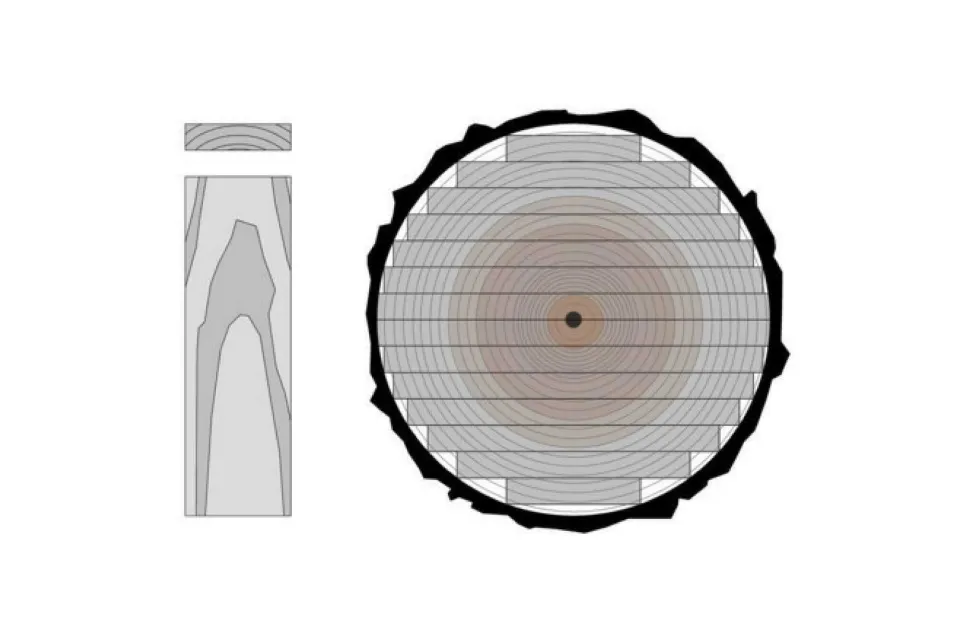

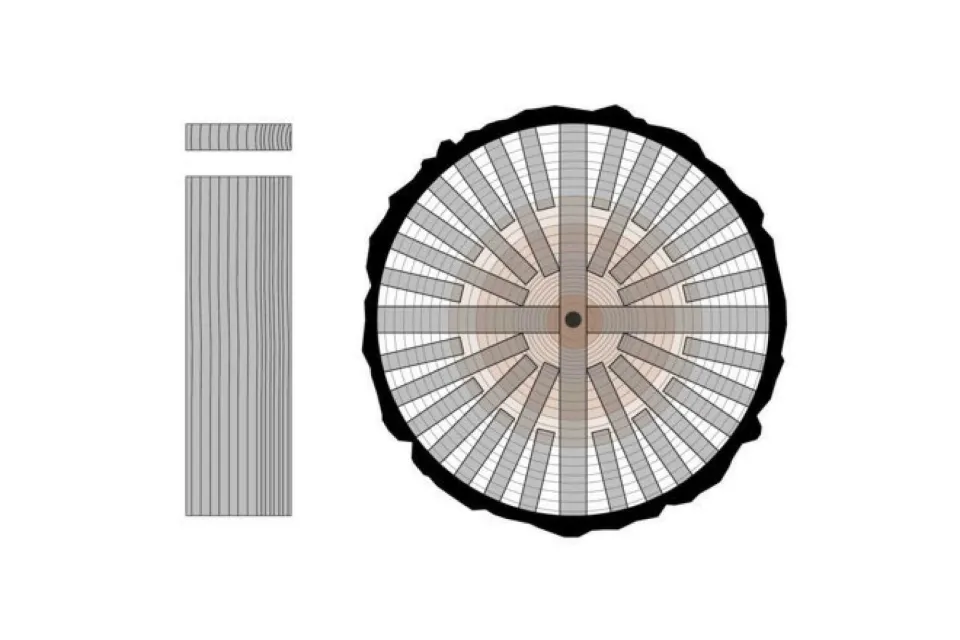

Certain timber cuts can be targeted to improve the drying and the overall exterior performance of exterior timbers. Some of the common sawmilling cuts can be found below:

Quarter Sawn

Quarter sawing involves breaking the log down in a manner where the grain is mostly vertical, this method is more efficient than rift sawing, and still provides a great result. Abodo’s Sand Decking features a vertical grain, achieved from quarter sawing.

A vertical grain orientation has three main benefits:

1. Stability

As wood tends to shrink and expand more tangentally compared to radially, the shrinkage and expansion is halved with vertical grain.

This means that coatings will last longer on timbers with vertical grain orientation.

2. Surface Cracking

In exterior applications, wood typically cracks perpendicular to the grain. This means that flat sawn timbers will have more visible cracking than quarter sawn, vertical grain boards. Surface cracks can harbour moisture, leading to premature decay - this means that vertical grain products last longer, and hold coatings better than those that are flat sawn.

3. Long Term Performance

Grain orientation has a significant effect on long term weathering. Flat grained timbers are more likely to show more surface cracking over time, while vertical grain pieces are less likely to crack.

Coatings will last longer on timbers with vertical grain orientation.