-

About

-

Products

- By Timber Product

- Cladding

- Decking

- Joinery

- Screening

- Panelling

- View all

- By Application

- Exterior Cladding / Siding

- Exterior Rain Screen

- Exterior Roofing

- Interior Walls & Ceilings

- Soffits

- Screening, Fins & Battens

- Windows, Doors & Joinery

- Posts & Beams

- Accessories + Samples

- Coatings

- Fixings

- Samples

-

Shop

- Samples

- Timber Samples

- Architectural Sample Box

- View all

- Accessories

- Coatings

- Fixings

- View all

-

Resources

- By Resource Type

- Technical Data Sheets

- Guides & Manuals

- Technical Articles

- Profile Drawings

- View all

- How To

- How To Specify

- How To Install

- How To Maintain

- Projects

- Contact

What is Thermally Modified Wood?

Thermally modified wood has grown rapidly in popularity, since the technology was first commercialised in the 1990′s.

Thermowood, originating from Finland, is now probably the most recognised brand. The process of thermal modification dramatically increases the durability and stability of wood – and results in a beautiful brown colouration. The result: a new, sustainable, environmentally friendly timber species.

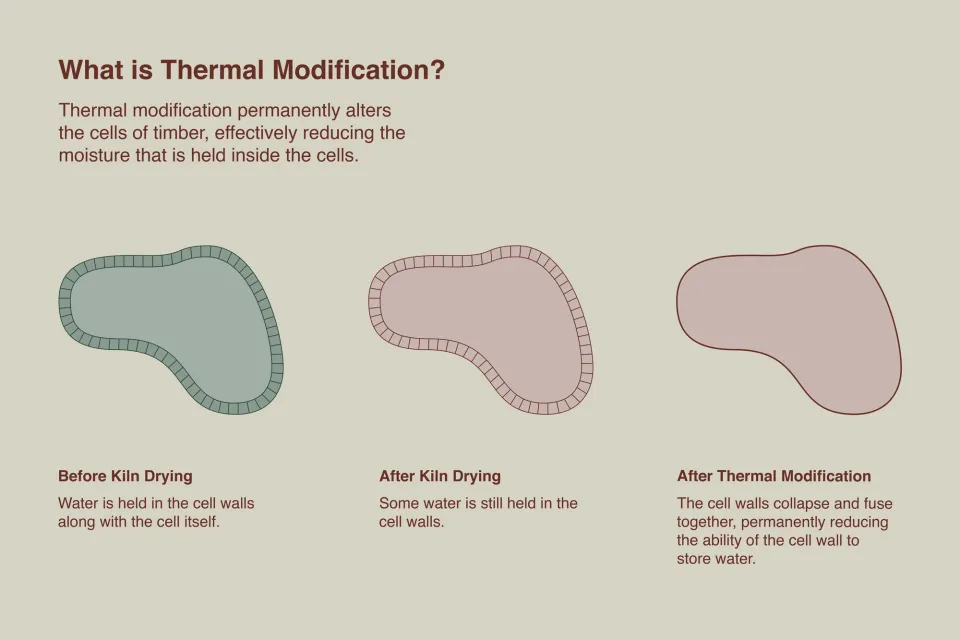

Thermal modification is achieved by using steam and high temperatures in excess of 190 degrees celsius. The real trick to the process is in the cooling and reconditioning phase. The modification process requires a purpose-built computer-controlled kiln to ensure every piece of timber is modified to the correct specification and quality. At the end of the process the moisture content of the timber is around 7% moisture content and the chemical and physical properties have been permanently changed.

In the image above, standard pine is shown on the left, thermally modified pine is on the right.

During the thermal modification process, many of the extractives are “cooked” out of the wood so that there is reduced chance of ‘resin bleed’ in service. This, combined with a degrading of the hemicellulose (sugar compound) in the wood, means that the conditions for fungal growth are greatly reduced.

As a result the durability of softwoods like radiata pine is increased to equivalent of H3 level – providing a 30 year expected service life in above ground vertical (cladding) applications. As an added advantage, thermal insulation properties are improved by around 20%.

All this is achieved without the use of wood preservatives or chemicals of any type. Thermally modified wood is perfect for eco decking, cladding and weatherboard applications, especially where “healthy” building materials are desired.

Abodo’s Vulcan Cladding is made from FSC® certified radiata pine clear wood modified in New Zealand with a custom Thermowood schedule at 230 degrees. Vulcan Cladding is available in a range bevel back, rusticated and vertical shiplap weatherboard profiles. The Vulcan system is CodeMark certified for compliance with the New Zealand building code.

This time lapse video shows the thermal modification process over a 32 hour period.